NHT – Your specialist for high-precision components made of tungsten, tungsten-copper, tungsten heavy-metal, molybdenum, TSM, and carbide.

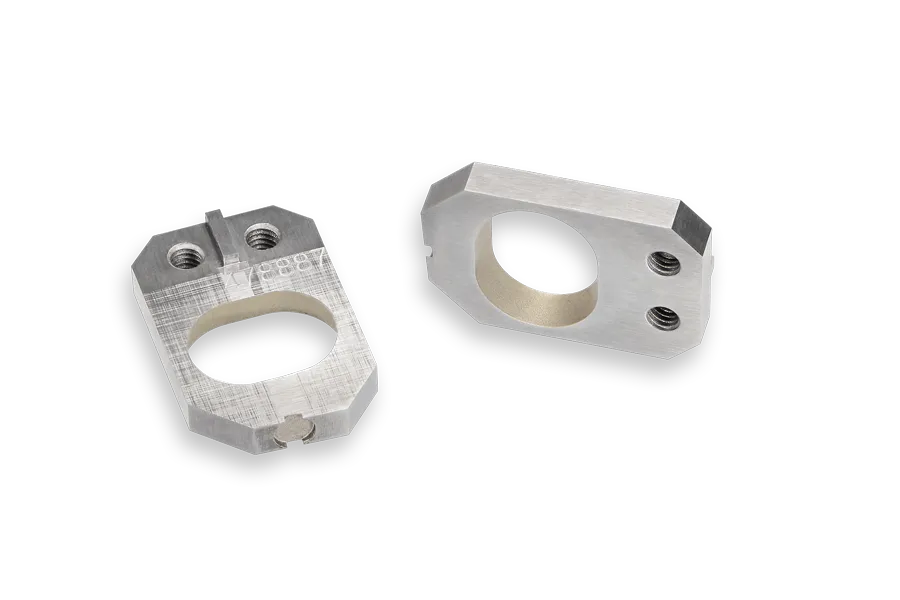

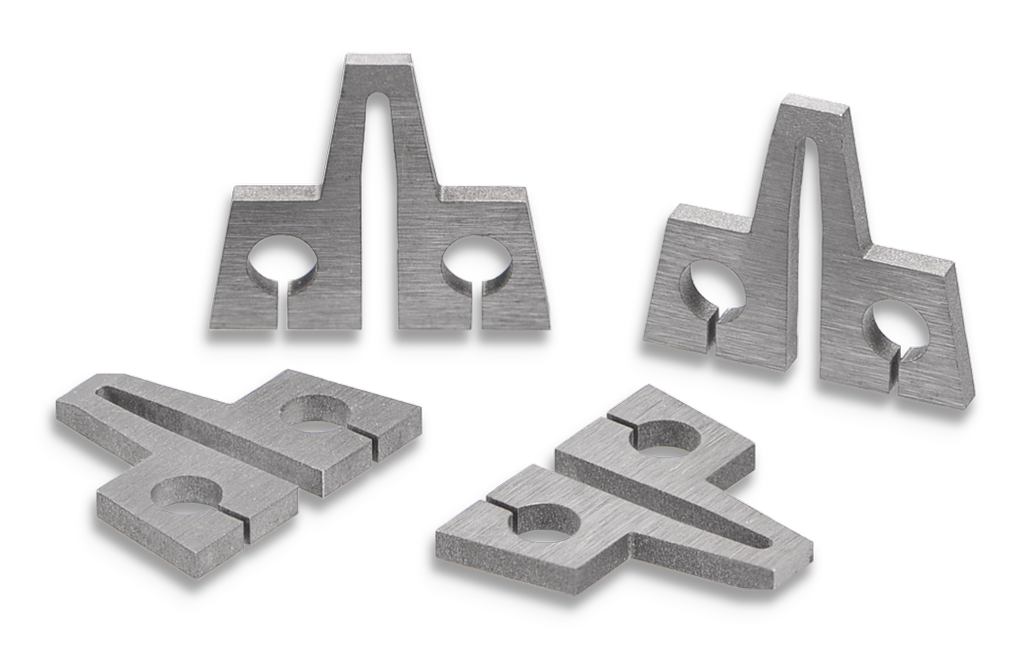

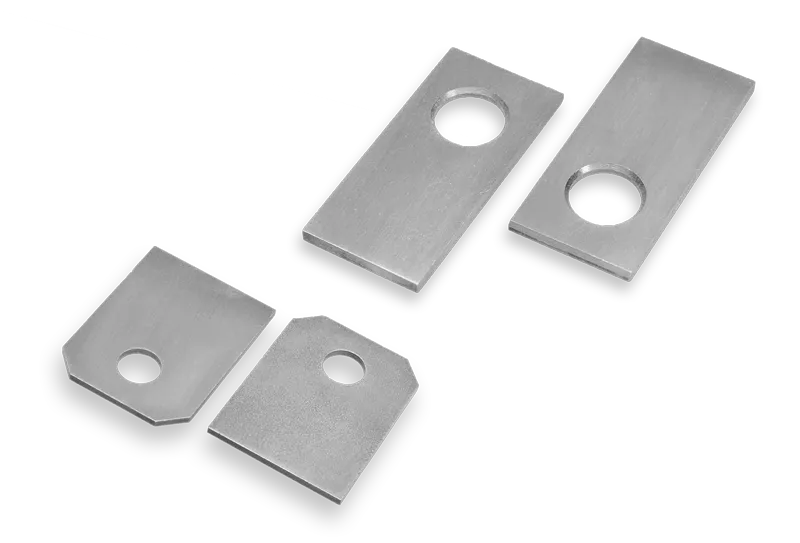

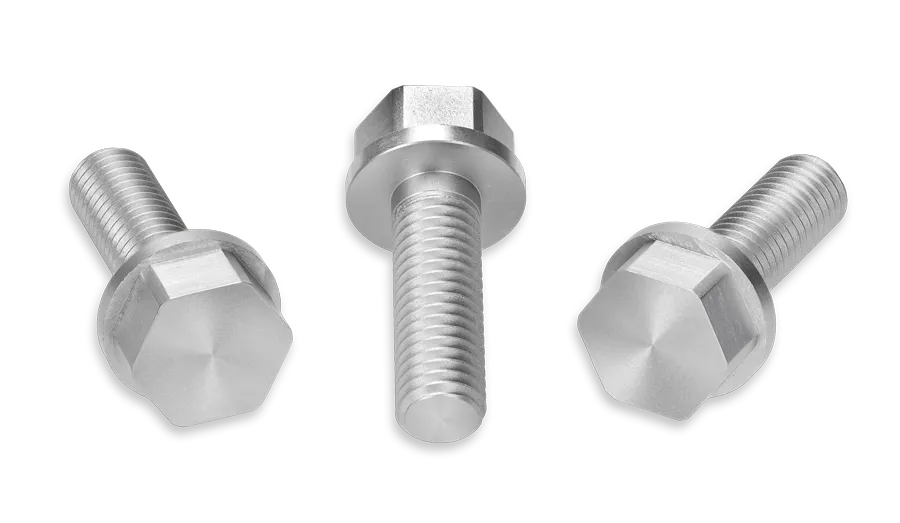

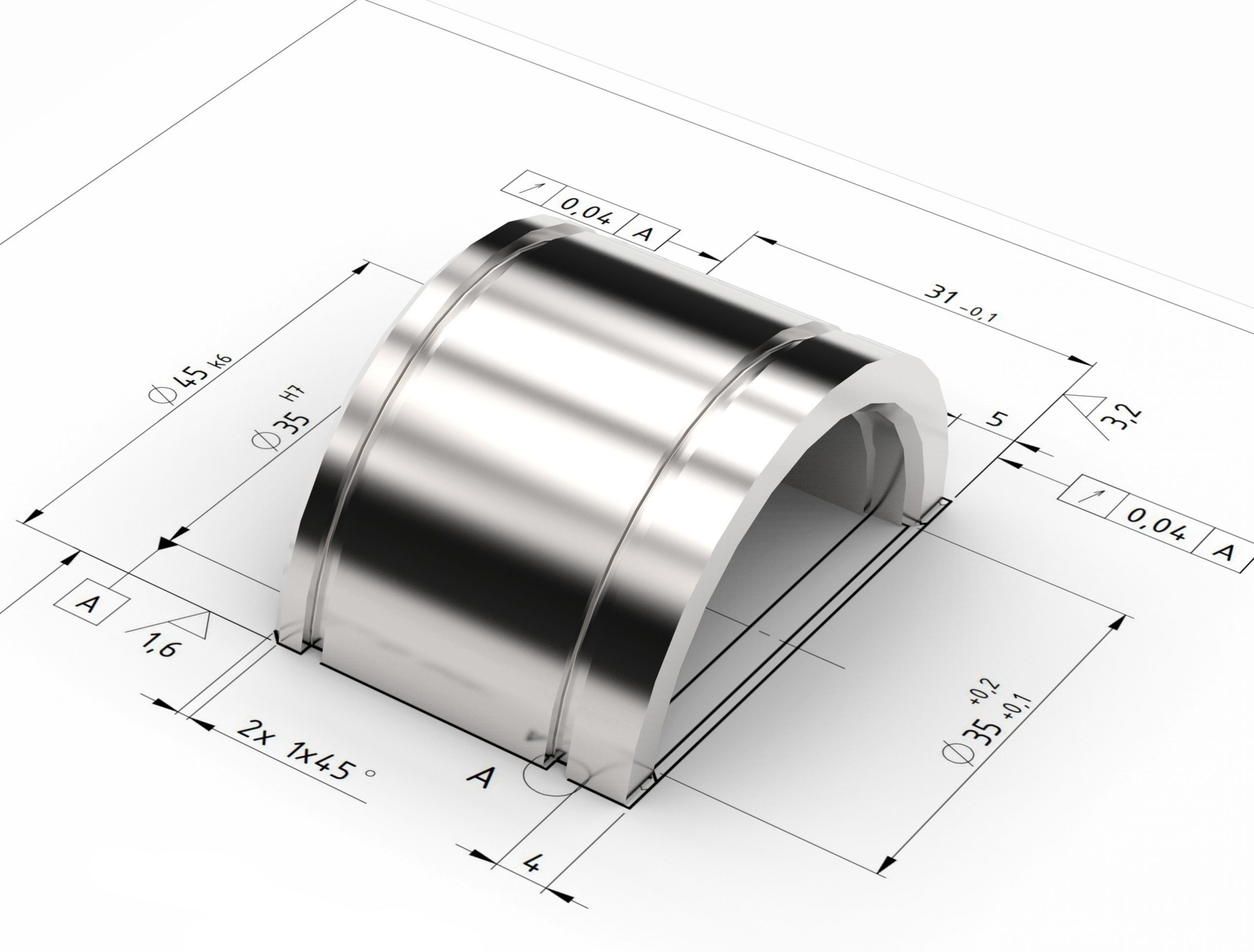

We manufacture one-offs and batch production precisely to your specifications – ranging from one-offs to prototype production and batch manufacturing.

Your benefits at a glance

Flexible one-off and batch production – precision at any scale

For more than 40 years, we have specialized on producing high-precision components and drawing components made of tungsten, tungsten copper, tungsten heavy-metal, molybdenum, TZM, and carbide. We also give you the ability to cost-effectively realize small lot sizes – flexible, accurately, and precisely to your specifications.

Based on our wide-ranging expertise with sintered tungsten materials (and molybdenum), we select the ideal material and optimize each production step for your application.

From one-off fabrication to batch production

We will manufacture your prototypes, individual components, drawing components, and custom components – in any quantity. We do so by relying on sophisticated methods for maximum precision and consistent quality:

- Wire EDM and vertical EDM,

- Flat, round, and ID grinding

- Centerless grinding

- Lapping

- Honing

- Coating

- Adhesive bonding

- Brazing

- Shrinking, and

- CNC machining.

Take advantage of our experience & flexibility – request your customized quote now.

Tailored project execution

We will give you a dedicated point of contact to support you throughout the entire process, from material selection, to production, and up to the final product. As a result, we can guarantee seamless and efficient processing.

More than production – our end-to-end service

- Residue-free surface cleaning for maximum cleanliness of your components.

- Taylored packaging solutions – on request, also in your own transportation packaging.

- Flexible warehousing: consignment warehousing, contract inventory on demand, or fixed delivery schedules – entirely to your needs.

Flexible quantities – no minimum order quantity

We give our customers maximum flexibility with regard to quantities, all without requiring a minimum order quantity. From one-offs to batch production: we manufacture high-precision components at attractive prices. Our agile manufacturing system gives us the ability to quickly respond to a wide range production requirements and changes and to continuously adjust the required capacity.

Fast & accurate – even for complex components

Our production process it is not only flexible but is also supported by a long-standing, validated network of experienced suppliers. As a result, we are able to cost-effectively manufacture complex components to drawing with maximum precision. Our warehouse also contains:

- Blanks and semifinished products, such as EDM plates and blocks, round rods, square rods, bushings, rings, and other molded components iaw. DIN-ISO.

- 20,000 different parts with more than 200 profile dimensions.

We can therefore fabricate customer-specific tools with a quick turnaround.

Top-shelf engineering support

Maximum efficiency for your company: we support you from the initial idea up to batch production and optimize your processes for longer tool life and reduced costs.

40 years of experience with carbide and tungsten – your partner for tailored solutions. We not only provide materials expertise but also optimize your processes, extend tool life, and cut costs.

Read more

From the initial idea to the final product, we work together with you to develop tailored solutions that are optimized to match your requirements and applications. Our objective is to optimize your processes and to increase tool life, thus reducing your costs for the long-term to continuously strengthen your competitive position.

In close cooperation with you, we develop materials optimized to meet your needs, while also providing extensive and competent engineering support during product development and optimization. Regardless of whether you are working on a long-term project or on a short-term (new) project – we are always at your side to find a best-possible solution or to optimize adjustments in response to changing requirements.

We will take care of the entire product process from the initial consultation, to material selection, and one-off and batch production, including subsequent warehousing and end-of-life recycling of raw materials to conserve resources. An end-to-end package for your peace of mind

Our comprehensive engineering know-how and our many years of experience allow us to continuely push the boundaries of what is possible. We think of ourselves more as an innovation partner who continuously optimizes existing solutions and, more importantly, who blazes new paths to give you real value added.

Your benefits

- Increased efficiency: optimized manufacturing processes allow you to conserve time and resources.

- Cost-reduction: our tailored solutions let you to work more profitably and efficiently.

- Sustainability: by selecting and using environmentally friendly materials, we assist your efforts toward responsible stewardship of the environment.

- Innovation power: take advantage of our know-how, drive, and our mutual desire to raise the bar.

Working together at eye level

We want to be your innovation partner. Regardless of whether you are looking for a long-term partnership or want to develop a new product – our objective is to work with you to create innovative solutions that stand out in terms of their engineering, profitability, and environmental impact.

Certified quality standard with batch and inspection certification

Maximum quality assurance, fully documented – for reliable results.

Maximum quality assurance, fully documented – for reliable results. Our products stand for inspected quality, seamless traceability, and full documentation. Every batch is analyzed in the lab in accordance with clearly defined standards and is shipped accompanied by all required inspection documentation. As a result, we generate trust – and give you the basis for reliable and standard-compliant processes

Seamless traceability of your shipment

Every shipment is assigned a unique batch number that provides on-demand traceability for all relevant production and inspection data – from the raw material source to the finished component. As a result, we not only meet statutory requirements, but also all industry-specific standards, such as ISO 9001:2015.

Extensive inspection certifications for your documentation

On request, each product you receive will be accompanied by corresponding records:

- Factory certification 2.1 confirms that the shipment matches the purchase order.

- Factory certification 2.2 confirms that the material matches specifications.

- Inspection certification 3.1: on request, we will prepare an inspection certification with specific metrology results.

First Article Inspection Report (FAIR/EMPB): as part of the first article inspection process prior to batch production, you will receive a complete FAIR/EMPB based on your requirements.

Your benefits at a glance:

- Quality verified based on lab analysis and inspection reports

- Full traceability of each batch

- Standard-compliant inspection certifications

- Tailored implementation of inspection requirements

- All documents are provided in digital form for your QA systems

Quality you can rely on

Our quality documentation is more than just a service – it is an integral component of our manufacturing process and part of our corporate philosophy. From automotive, machine construction, or medical devices: we supply you with the records you require – accurately, transparently, and in compliance with standards.

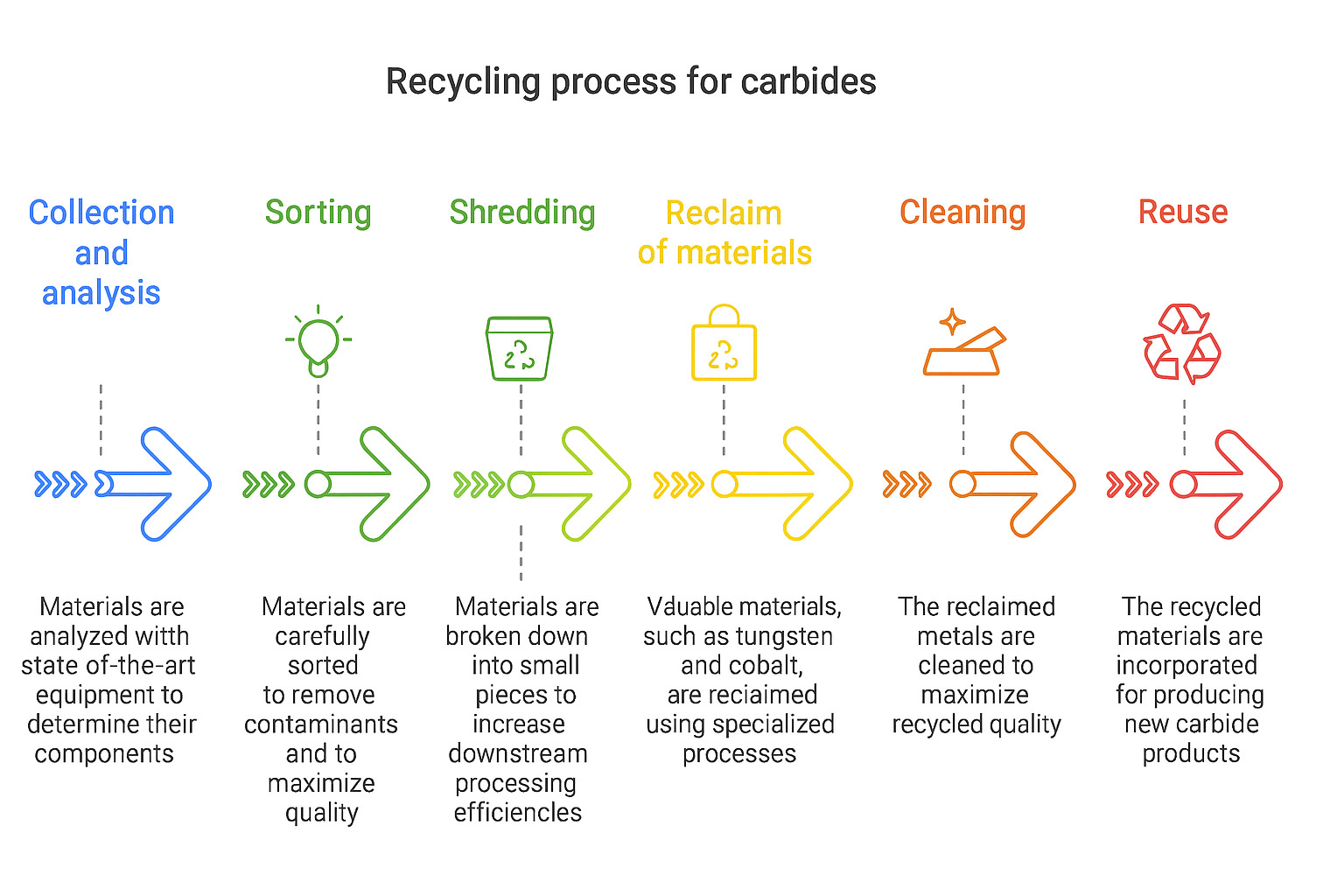

Sustainability by recycling carbide and tungsten

We are committed to sustainability: we recycle carbides and tungsten alloys to:

- Reduce the CO₂ footprint

- Conserve resources

- Reduce material costs for our customers

- Reduce the requirements for rare earth materials and to reduce supply chains dependencies

Efficient recycling allows us to reduce the dependence on primary raw materials and strengthen a sustainable and reliable raw material supply.

Together for a sustainable future: the more raw materials are recycled, the more effectively limited resources can be kept in circulation.

What materials do we recycle for you?

We will reclaim a variety of raw materials for recycling, including:

- Machining inserts

- EDM blocks

- Drills

- and many other carbide products

- Electrodes made of tungsten alloys

This is how our recycling process works:

Your benefits as a customer

- Cost reductions: reduce your material costs by using recycled raw mate.

- Sustainability: demonstrate within your business and to your customers that your actions are responsible and environmentally conscientious.

- Easy processing: we take care of the entire recycling process from pickup to recycled raw material – quickly, efficiently, and conveniently.

Easy processing with NHT:

- Contact your personal in-house sales consultant or send an email to recycling@negele-hartmetall.de.

- Tell us about the type of materials and an approximate weight.

- We take care of all the rest – from providing the transportation box, to return shipment, and even including environmentally friendly recycling of your materials.