Carbide

Hard as diamond. First introduced by Krupp in 1926 under the brand name “Widia”, the name of this material says it all.

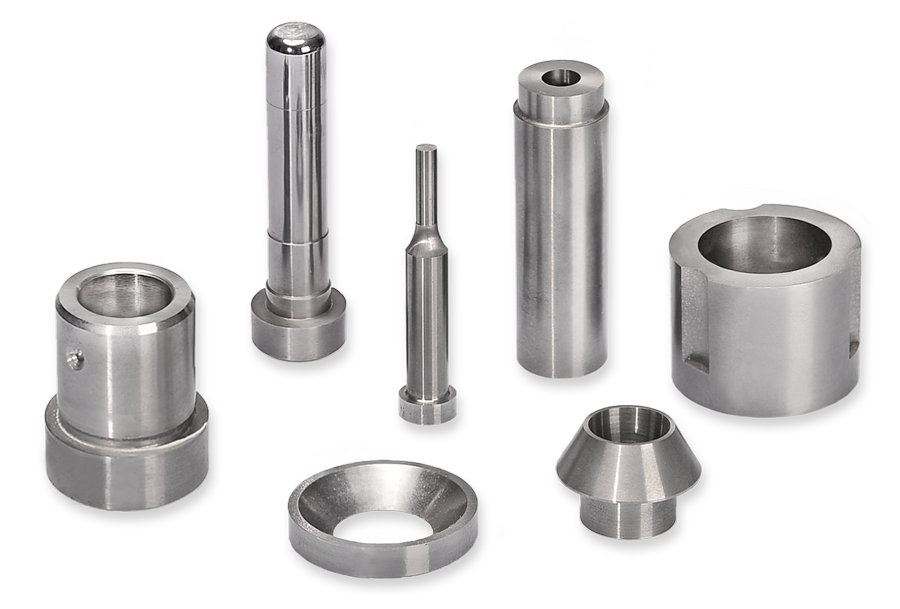

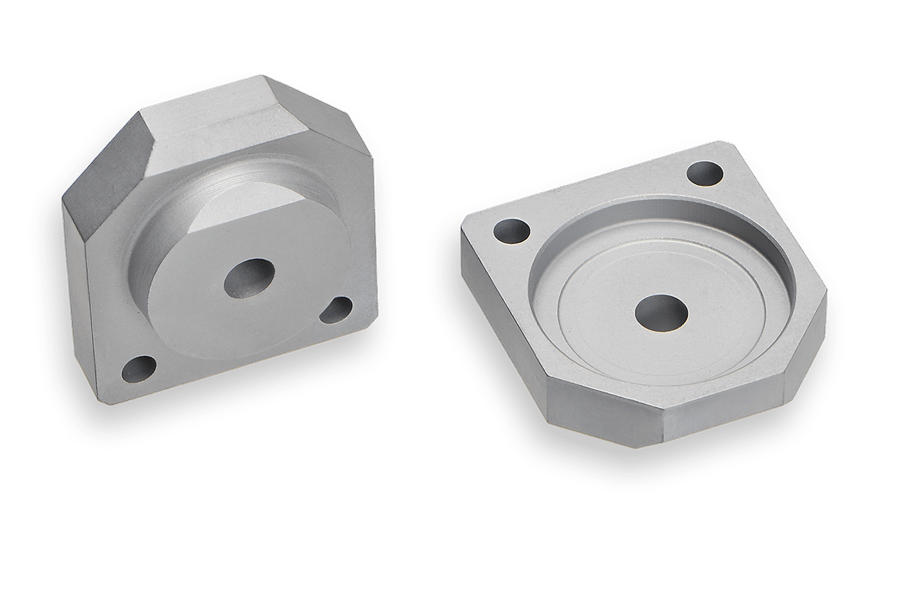

Our carbides are available in any form – as blanks or as ready to use carbide components.

Having a hardness of up to 2000 HV, this material will stand up to even the toughest requirements. Our extensive experience in a wide range of industrial sectors has resulted in carbide grades with the precisely correct material composition for various applications.

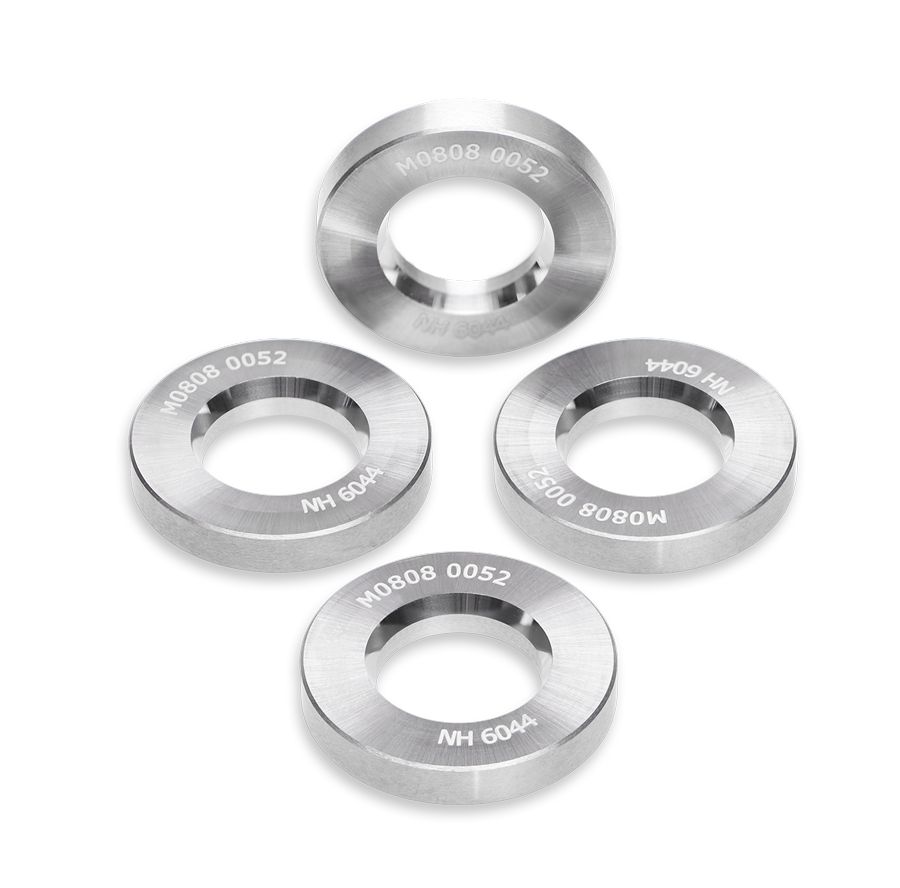

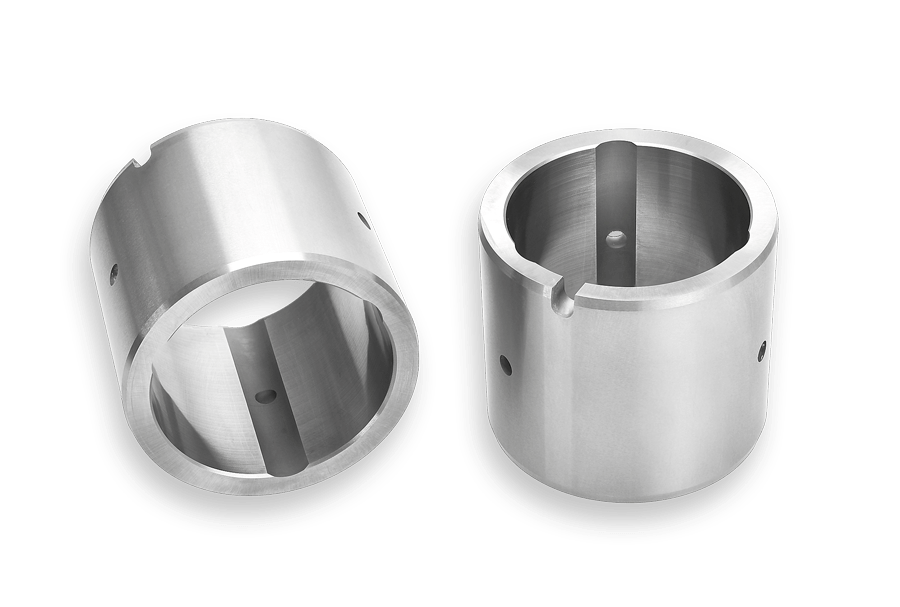

Our carbide products are used as guide and drill bushings, rings and round rods, nozzles and valve components, parts for metrology and inspection equipment, molds for ceramic and porcelain manufacturing, cutting inserts and molds iaw. DIN standards, factory standards, to customer drawings, drawing and deep drawing tools, molds, inserts for powder and ceramic press tools, and for screw and nut manufacturing.

The extraordinary versatility of a carbide will secure its outstanding role as a material for wear and machining applications, in corrosion protection, mold engineering, and for stone and mining operations.

- Brazing plates for single-tip or multi-tip brazing tools for processing metals, wood, and engineered wood, graphite, plastics, and rock

- Solid carbide tools for drilling, turning, milling, deep drilling, parting, and many others

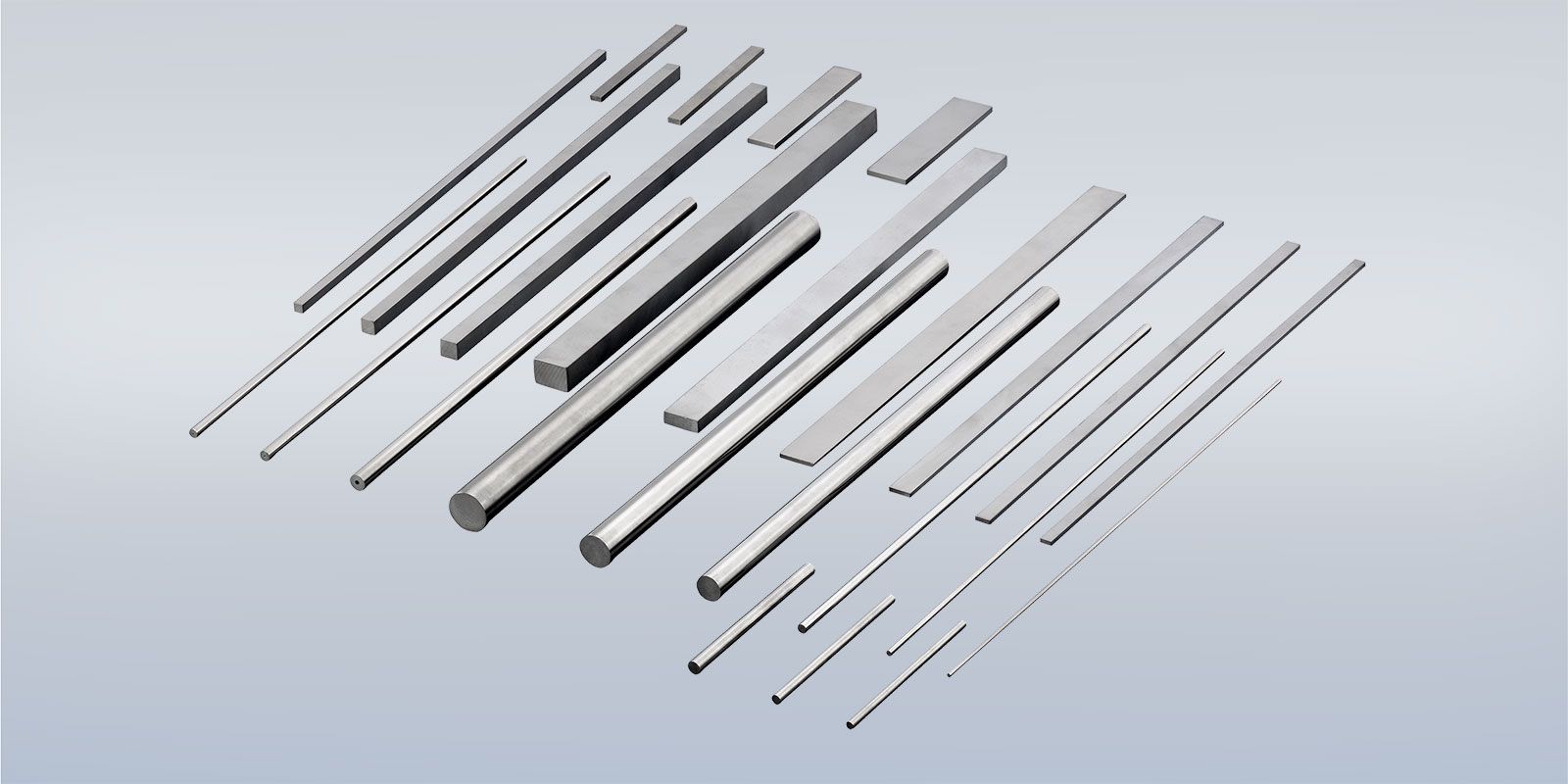

- Carbide rods with round, square, rectangular, or trapezoidal shapes, and for manufacturing specialty tools

- Sandblasting nozzles in standard and venturi configurations

- Jet nozzles for spraying and precision spraying of powders and liquids

- Press tools and extrusion tools for manufacturing ceramics, fire-resistant substances, and cement bricks

- Molds and punches for pressing metal powders

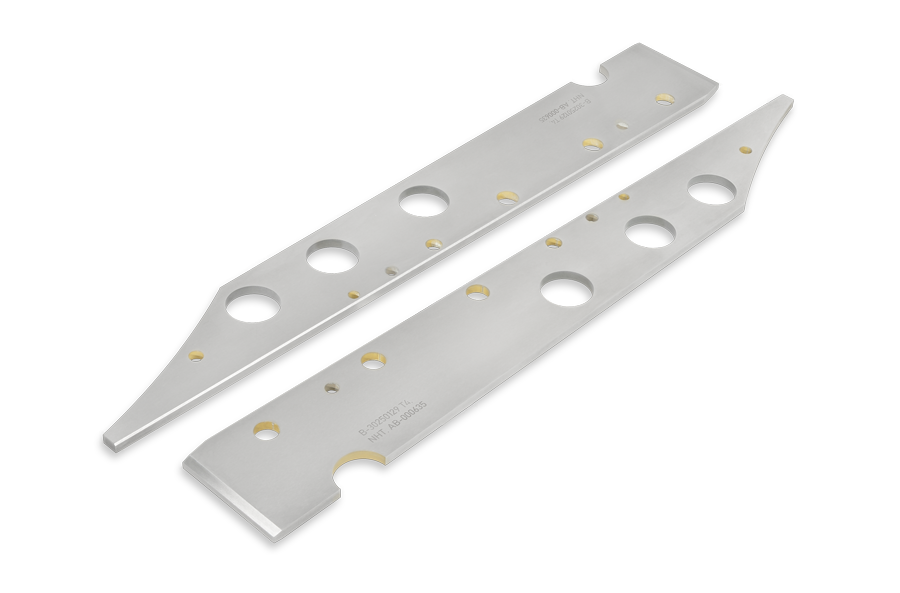

- Rotating knives for paper and printed circuits

- Shearing knives for plastics and sheetmetal

- Mechanical seals

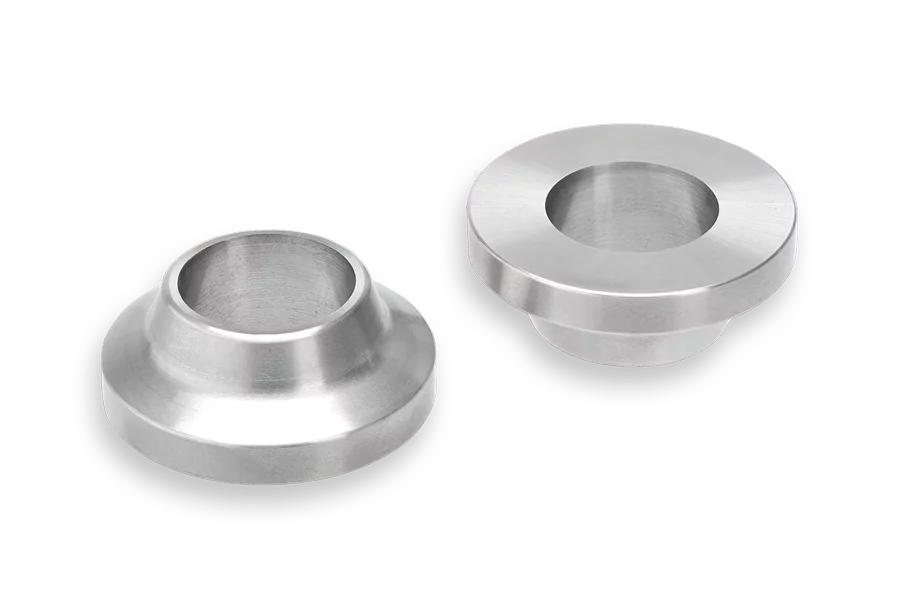

- Valve shafts and valve seats

- Wire and rod guide bushings

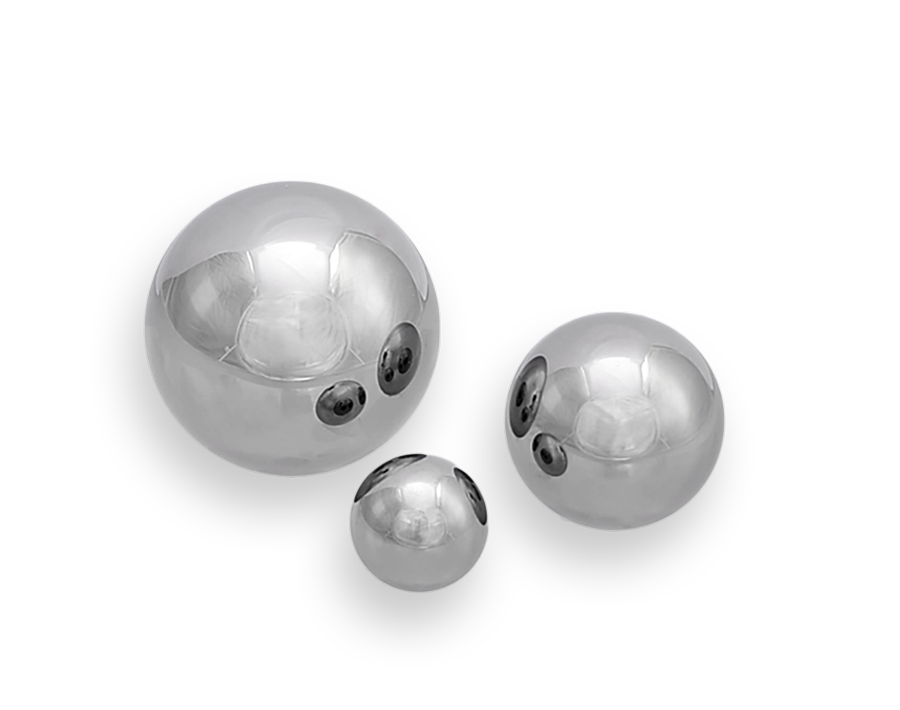

- Milling balls

- Carbides made of corrosion-resistant alloys for surgical, chemical agricultural, food-processing, and crude oil applications

- Rolling mill, cams, and rotating rollers

- Round and formed extruded bricks with as-sintered bore diameters from 0.10 mm

- Mandrels

- Cores for cold-forming tools

- Plates for wire shears

- Nut dies

- Deburring dies

- Dies and punches for deep-drawing and extrusion pressing of non-ferrous alloys

- Parts for stamping tools

- Dies and punches for munitions tools

- Inserts for drilling heads and mining tools of all types

- Plates for parting and turning granite, marble, alabaster, and tuff

- Plates for manual and mechanical chisels and for bush hammering machinery

- Plates for porphyry shears

- Chisels for asphalt millers

- Glass and tile cutter wheels

- Specialty parts for machinery to break down rocks and minerals

Careful monitoring of material compositions and constant innovation of new manufacturing and testing methods ensure the outstanding chemical and mechanical properties of carbides.

Properties

- Maximum wear resistance

- High, flexible hardness range

- High flexural strength

- High modulus of elasticity and high stiffness

- Maximum compressive strength, good ductility

- Good corrosion resistance

- Outstanding thermal conductivity

- Better thermal resistance than steel grades

Applications

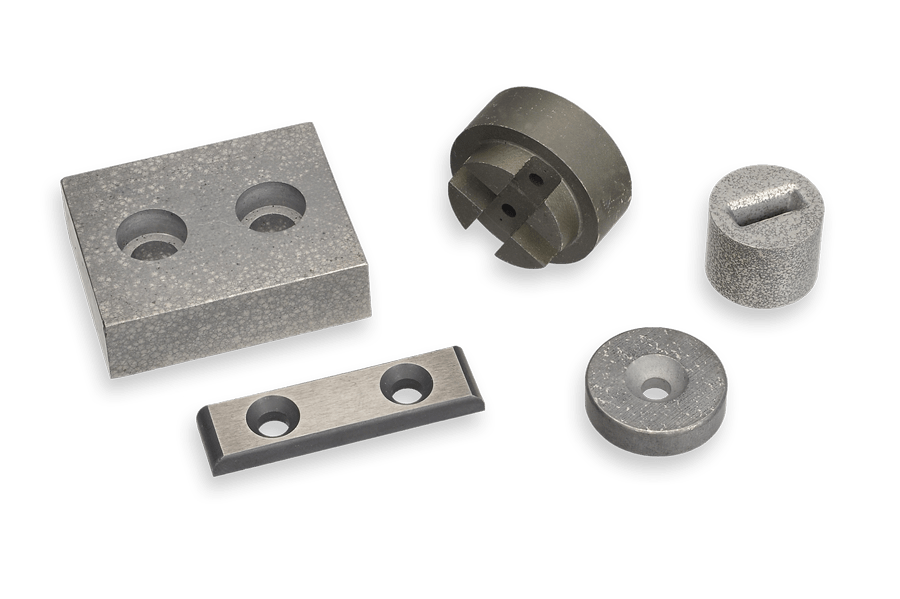

- Inserts, cutting bushes, and punches for stamping tool

- Molds, punches and dies for pressing powdered metals and ceramic compounds

- Bearing rings, valve parts, jet nozzles for powders and liquids

- Machining tools of all types

- Knives for paper, plastics, sheetmetal, and printed circuits

- Wear parts for maximum requirements in machine construction and tool making applications (joining by brazing, gluing, screws, clamps, shrinking, and potting)

Delivery forms

- Formed parts to drawing with short leadtimes

- Profile rods

- Tubes

- Plates for wire EDM

- Formed parts iaw. DIN ISO standards

Multi-range carbide grades

We can supply all carbide grades, precisely matched to your specific needs, starting with our proven standard grades, continuing with universal multi-range grades, and ending with our specialty grades. The different properties of the individual grades are achieved with various mixture ratios of the components, and by selecting and combining the tungsten carbide grain shape and grain size, along with precisely matched process controls.

NHT has specific grades in outstanding quality for any requirement.

NHT fine-grained grades

In response to permanently increasing requirements for our carbides, we created innovative solutions in particular based on our highly-densified fine-grained grades GM05F, GM10F, GM15F, GM25F.

The fine-grained grades give you the following benefits compared to standard grades:

- Very high ductility behavior based on high flexural strength – up to 3900 N/mm²

- Maximum wear resistance due to high hardness – up to HV 2000

- High edge stability due to a very fine, dense, and homogenous grain structure; as a result, these materials are particularly suited for punching and cutting tools.

Contact

Do you have a question or a suggestion? Do not hesitate to contact us. You can find the right contact person for your topic here.

Phone: +49 (0) 711 97948 – 0

Materials

Tungsten, tungsten-copper, tungsten heavy alloys, molybdenum, TZM or hard metal: our high-performance materials for your individual requirements.

Blanks from stock – fast shipping

We deliver over 20,000 parts in over 200 different profile dimensions directly from stock.

You order and we will ship on the day of the order!