Powerful know-how for strong high-performance materials

Tungsten, tungsten-copper, tungsten heavy-metal, molybdenum, TZM, and carbide: our high-performance materials for leading-edge requirements. Do not hesitate to contact our technical consultants to determine what material specification is right for your application.

Tungsten / Tungsten alloys

Tungsten has an extremely high melting point. It is therefore most commonly used for electrodes.

Low burn-off propensity, good electrical conductivity, high thermal conductivity, and low thermal expansion: our tungsten-copper.

We alloy our tungsten with small additions of Lanthanum oxide. This improves creep resistance while also increasing the recrystallization temperature.

Compared to tungsten, our tungsten heavy-metal is characterized by its higher density. This ensures significantly improved machinability and advantageous mechanical properties.

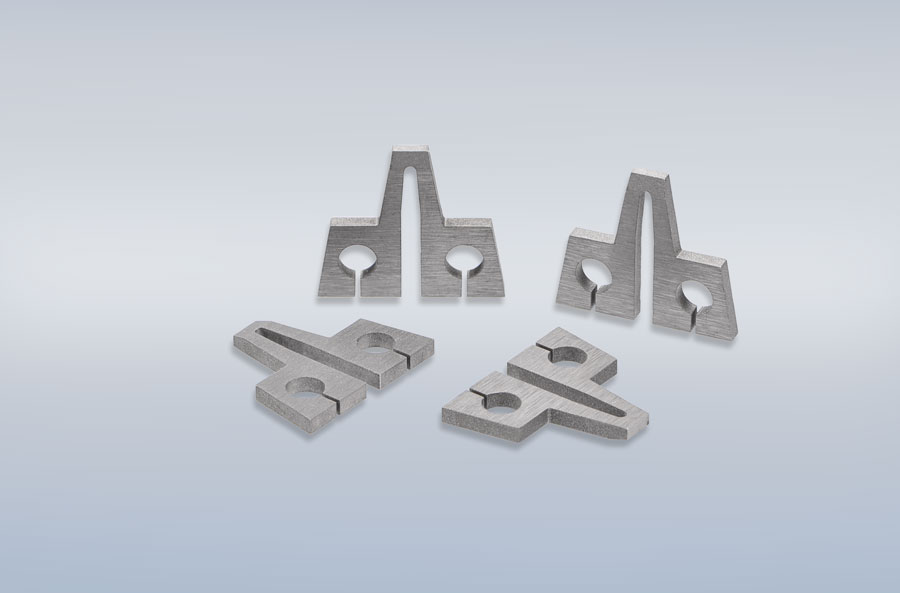

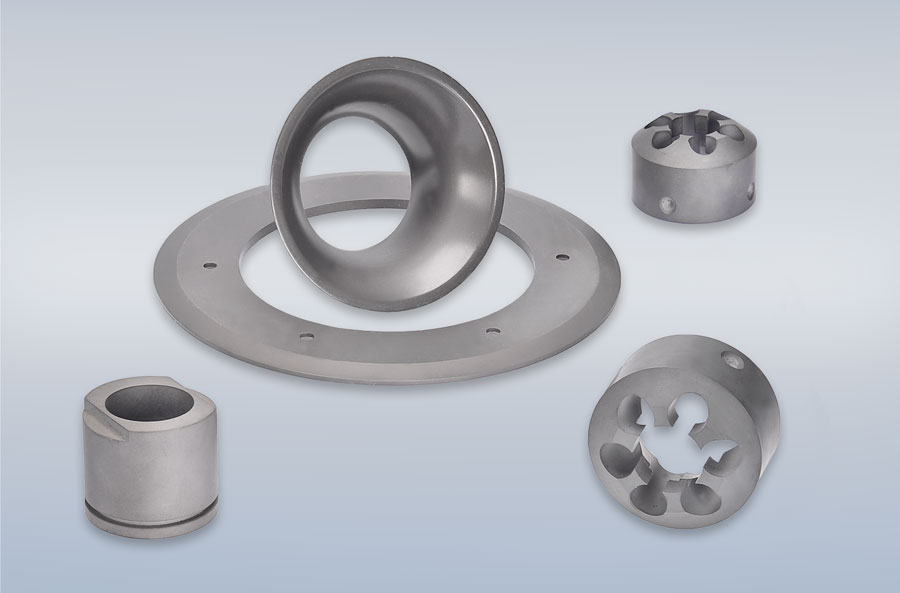

Carbide

Our allround grade for machining, punching, and free machining of medium and heavy gauge sheetmetals, and the universal grade for steel and nonferrous metals.

The EDM-compatible grade with corrosion protection for extended presence in the dielectric. The grade compels with its outstanding surface finish, while also requiring less post machining. The material therefore holds its shape better and has longer tool life.

Our grade for high wear-resistance while also featuring good toughness. This corrosion-resistant alloy is exceedingly suited for manufacturing parts for surgical, chemical, and agricultural applications, and also for the food processing and crude oil industries.

Molybdenum / molybdenum alloys

Compared to pure molybdenum, molybdenum-lanthanum oxide has better creep strength and a higher recrystallization temperature, resulting in improved machinability.

AGiven its high temperature resistance and good machinability, molybdenum is frequently used in aerospace applications.

TZM is stronger than pure molybdenum and has a higher recrystallization temperature (by ≥250 °C) and higher creep strength.

Molybdenum is a composite material with up to 35% copper content. This ideal combination unites the high thermal conductivity of copper with the low thermal expansion of molybdenum.

Contact

Do you have a question or a suggestion? Do not hesitate to contact us. You can find the right contact person for your topic here.

Phone: +49 (0) 711 97948 – 0

Materials

Tungsten, tungsten-copper, tungsten heavy alloys, molybdenum, TZM or hard metal: our high-performance materials for your individual requirements.

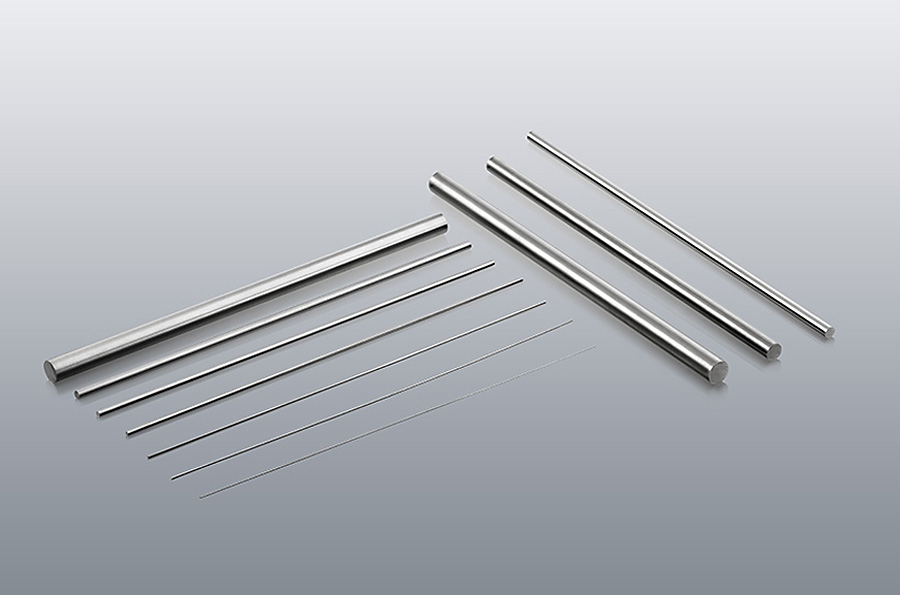

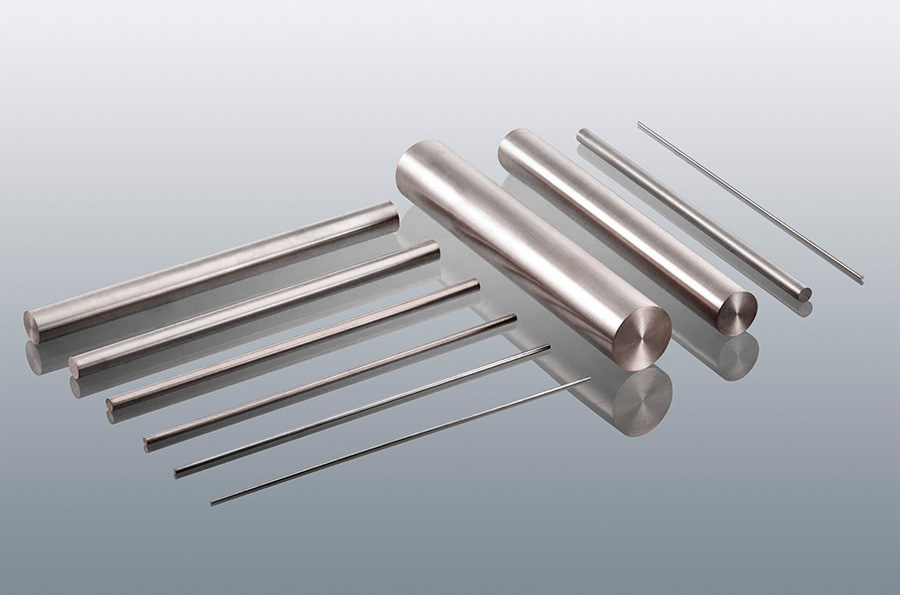

Blanks from stock – fast shipping

We deliver over 20,000 parts in over 200 different profile dimensions directly from stock.

You order and we will ship on the day of the order!