Molybdenum (Mo)

A tongue-twister but nevertheless valuable beyond words! We supply molybdenum at a purity of more than 99.8%. Like tungsten, molybdenum is a high melting-point refractive metal with outstanding thermo-physical, mechanical, and chemical properties.

Molybdenum is resistant to most acids, alkaline solutions, and non-metals. At temperatures above 100 °C, molybdenum is unstable in oxidizing and alkaline fluids. It is highly stable against hydrogen, nitrogen, inert gases, glass, and metal melts – even at very high temperatures. By alloying with other high melting-point metals, the corrosion resistance to certain media can be increased even further. Compared to tungsten, molybdenum can already be shaped and easily machined at low temperatures.

The brittle-ductile temperature during forming must be observed – the thicker the material, the higher the heating temperature. Above the brittle-ductile temperature, molybdenum loses its brittleness – it can be reliably formed without cracks. Cutting, stamping and machining are also possible at the correct heating temperature.

Through targeted and precisely controlled alloying measures, we achieve molybdenum alloys with further optimized properties – precisely tailored to the highest requirements in the high-tech sector.

For example: Molybdenum-Lanthanum (ML), Titanium-Zirconium-Molybdenum (TZM), Molybdenum-Copper (MoCu), Molybdenum-Tungsten (MoW) etc.

Properties

- High melting point 2620 °C (2893 K)

- Low vapor pressure

- High modulus of elasticity

- Extremely high thermal resistance and creep strength

- High thermal conductivity

- Low coefficient of thermal expansion

- Outstanding corrosion resistance

- Good machinabilit

Applications

- Mixers in glass and metal melts

- As carrier for power electronics in semiconductor manufacturing

- Components, heater inserts in tempering furnaces, sintering lines

- Vapor deposition crucibles

- Thermal protection tubes

- Glide coatings

- Power feeds for incandescent bulbs

- Wire mesh

- Dimming shields in motor vehicle lights

- Components in the chemical industry

- Catalytic converter components

- Heat sinks

Available formats

- Wires

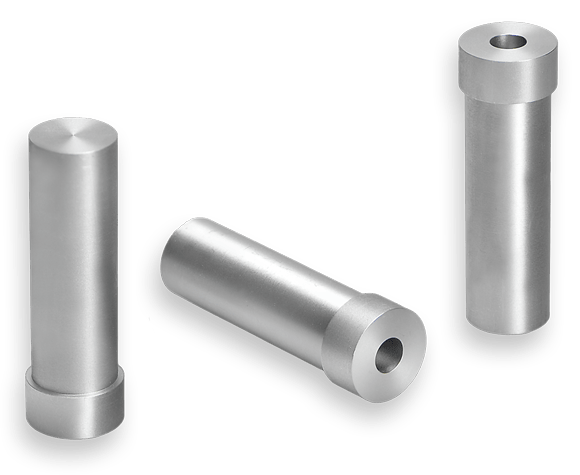

- Round rods

- Profiles

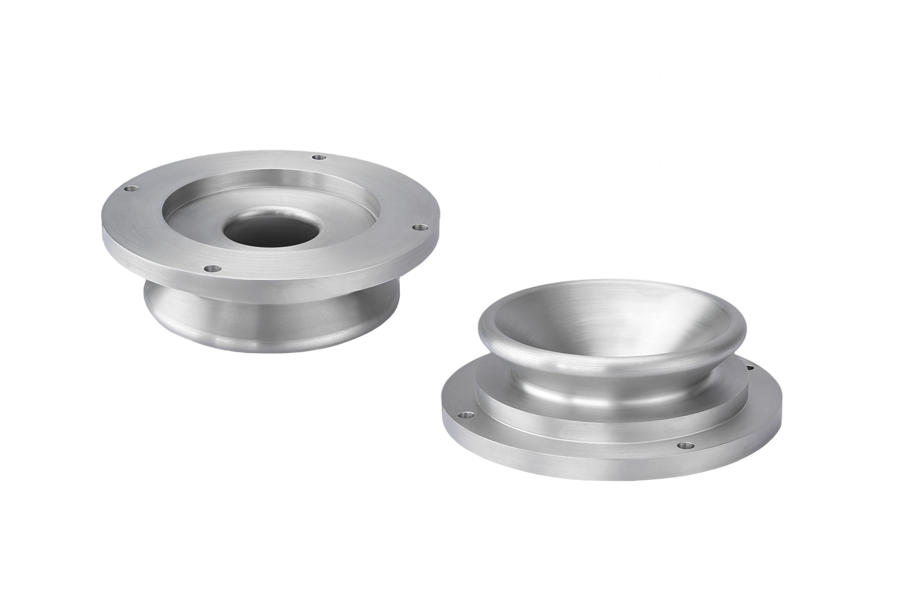

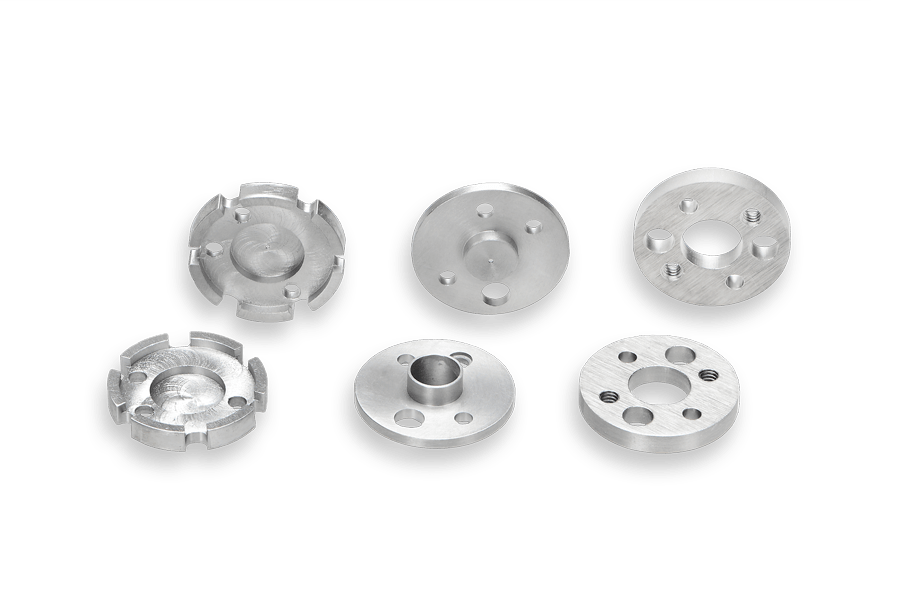

- Formed parts to drawing

Contact

Do you have a question or a suggestion? Do not hesitate to contact us. You can find the right contact person for your topic here.

Phone: +49 (0) 711 97948 – 0

Materials

Tungsten, tungsten-copper, tungsten heavy alloys, molybdenum, TZM or hard metal: our high-performance materials for your individual requirements.

Blanks from stock – fast shipping

We deliver over 20,000 parts in over 200 different profile dimensions directly from stock.

You order and we will ship on the day of the order!