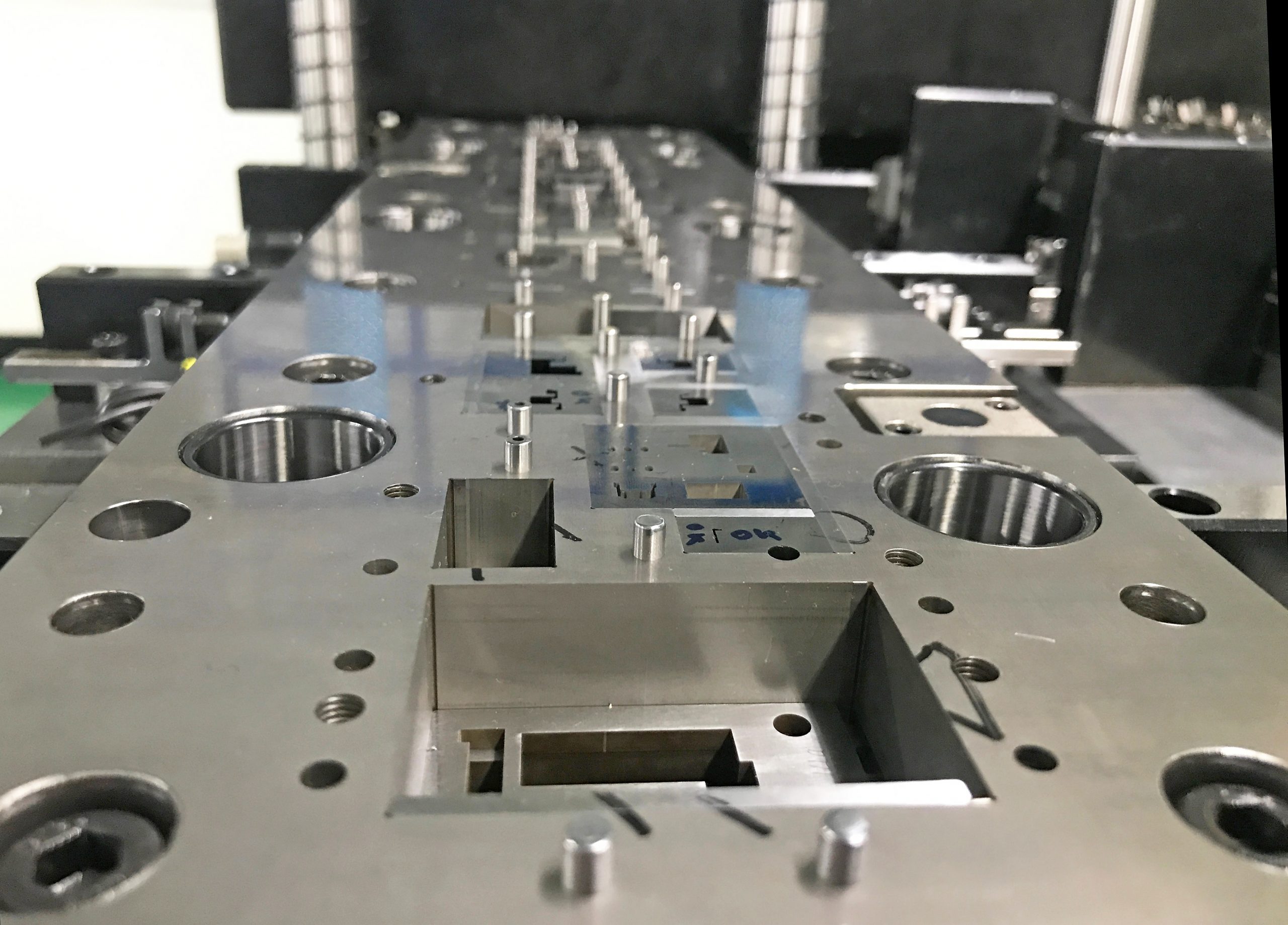

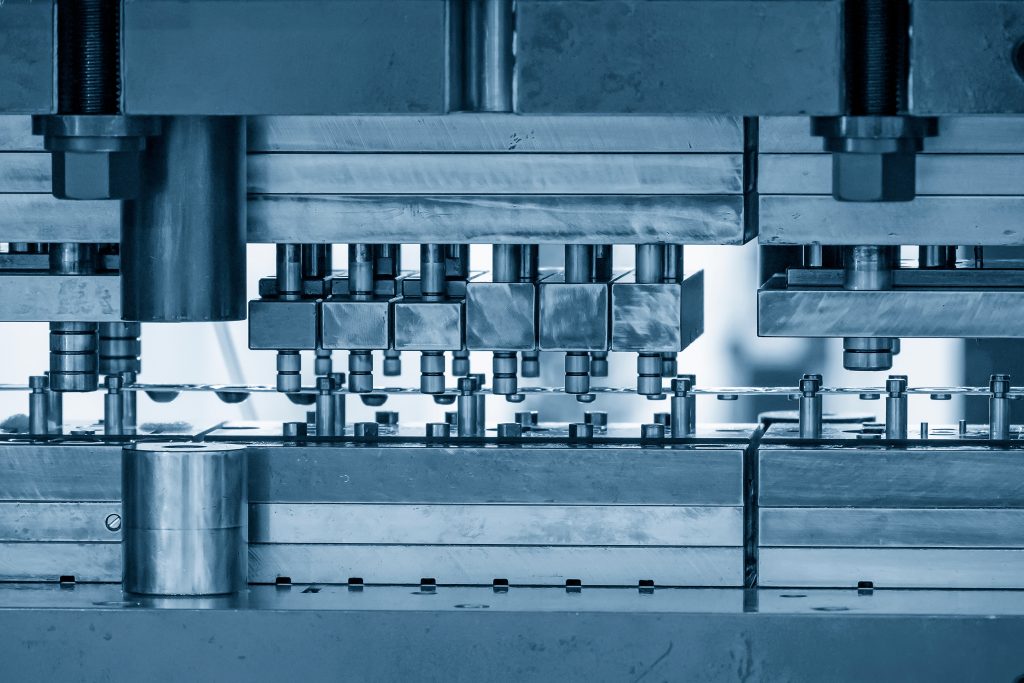

Tool-making / forming technology

Precision, contour accuracy and process capability are requirements for tool-making and forming technology. NHT offers solutions that compel with optimized tool performance and stability over its entire service life.Applications for NHT high-performance materials

In these applications, our carbide in particular is able to play to its strengths, but other materials from our product line are also in demand.- Carbide punches

- Molds

- Blanking sleeves for punch tool-making

- Tools for cold-forming, drawing inserts, and molds

- Forging pads

- Embossing dies

- Bending dies

- Forging dies

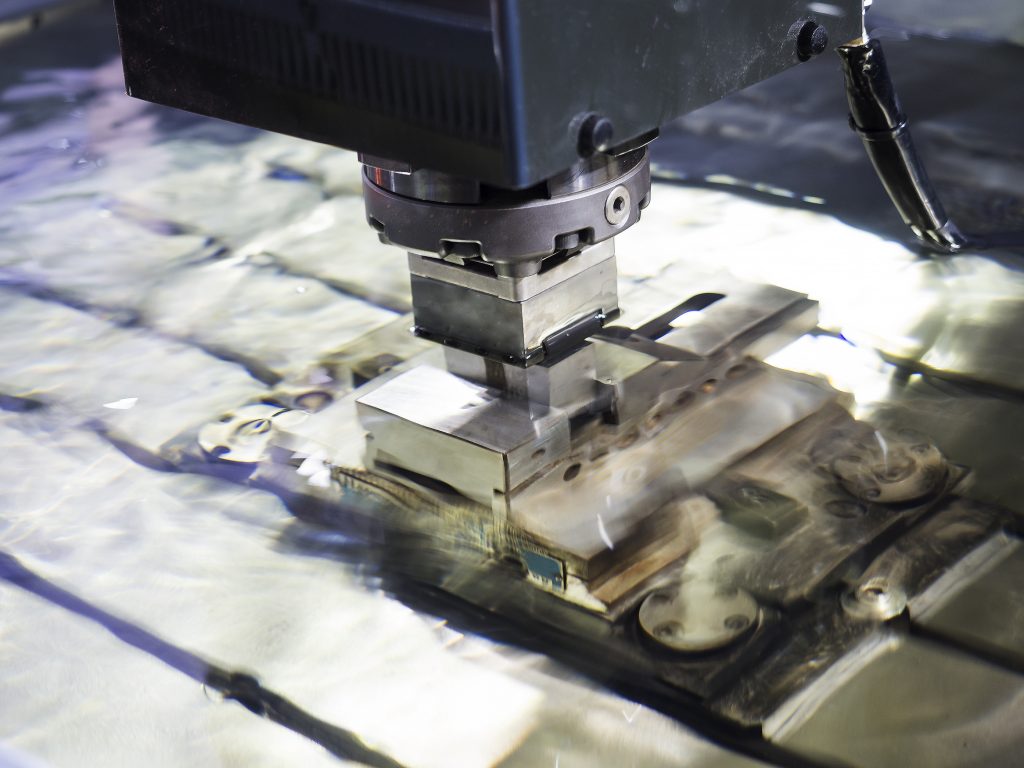

- Sinker electrodes made of TCu

- Cup electrodes

- Disc electrodes

- Insert rods

Our carbide tools compel with their extremely high wear-resistance and are used where maximum precision and long tool life is required.

Our tungsten-copper is primarily used for sinker EDM processes. The key properties of this material include resistance to erosion, good electrical conductivity, high thermal conductivity, and low thermal expansion.

Contact

Do you have a question or a suggestion? Do not hesitate to contact us. You can find the right contact person for your topic here.

Phone: +49 (0) 711 97948 – 0

Materials

Tungsten, tungsten-copper, tungsten heavy alloys, molybdenum, TZM or hard metal: our high-performance materials for your individual requirements.

Blanks from stock – fast shipping

We deliver over 20,000 parts in over 200 different profile dimensions directly from stock.

You order and we will ship on the day of the order!