Tungsten

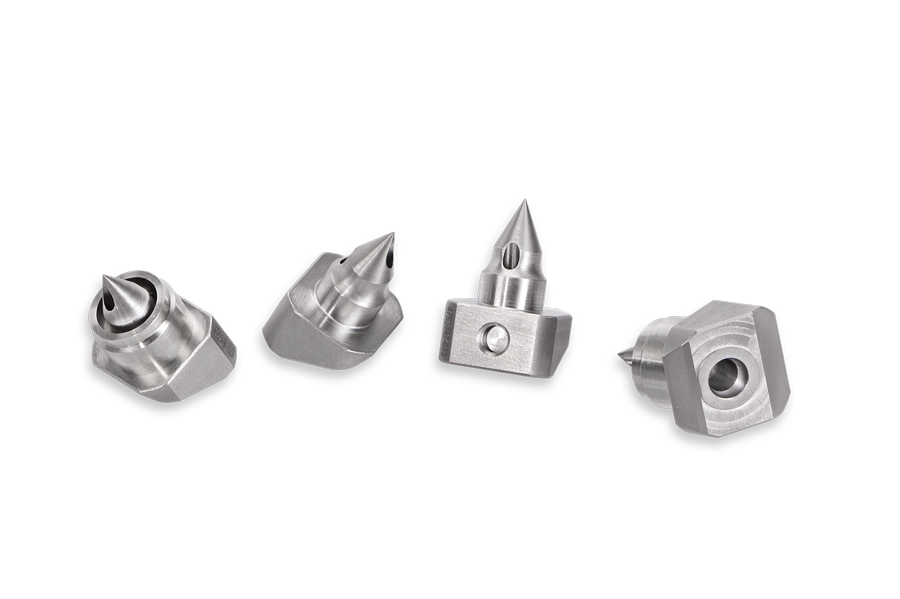

Its strength is “white hot”, therefore allowing applications up to 2900 °C (3173 K). This also explains the probably most frequent use as the glow wire in incandescent bulbs.

In terms of its physical and chemical values, tungsten embodies the typical properties of refractive metals. These include all metals whose melting point is above that of platinum (1772 °C). Tungsten is primarily used as a base material in many tungsten alloys, such as tungsten-lanthanum oxide (TL), tungsten heavy-metal (THM) and tungsten-copper (EROMET). In its pure form, it is used in far fewer applications, such as crucibles for the coating industry, and as a heat shield and for heating elements.

Properties of tungsten - tungsten alloys

As a powdered metal, tungsten is manufactured with a purity of 99.95 %. Chemically pure tungsten has outstanding properties, such as:

- an extremely high melting point (3420°C) – the highest of all metals – while also having a low vapor pressure (at 2000°C < 4 ∙ 10-9 Pa)

- a high modulus of elasticity

- good thermal resistance at a low coefficient of thermal expansion

- a high density of 19.3 g/cm³ (at 20 °C)

- good chemical resistance against inorganic acids, alkaline solutions, organic acids, non-metals, glass without oxidizers, glass melts, and gases

- high corrosion resistance against metal melts

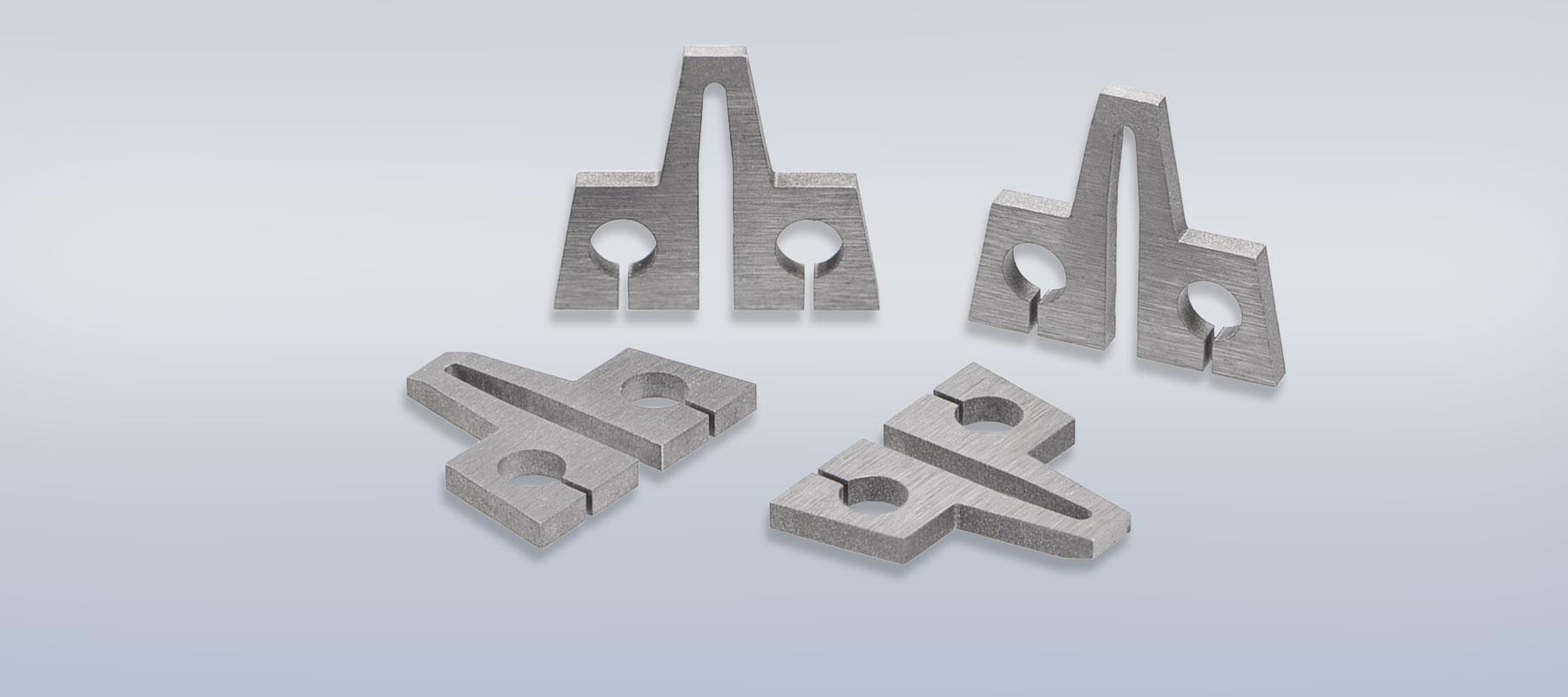

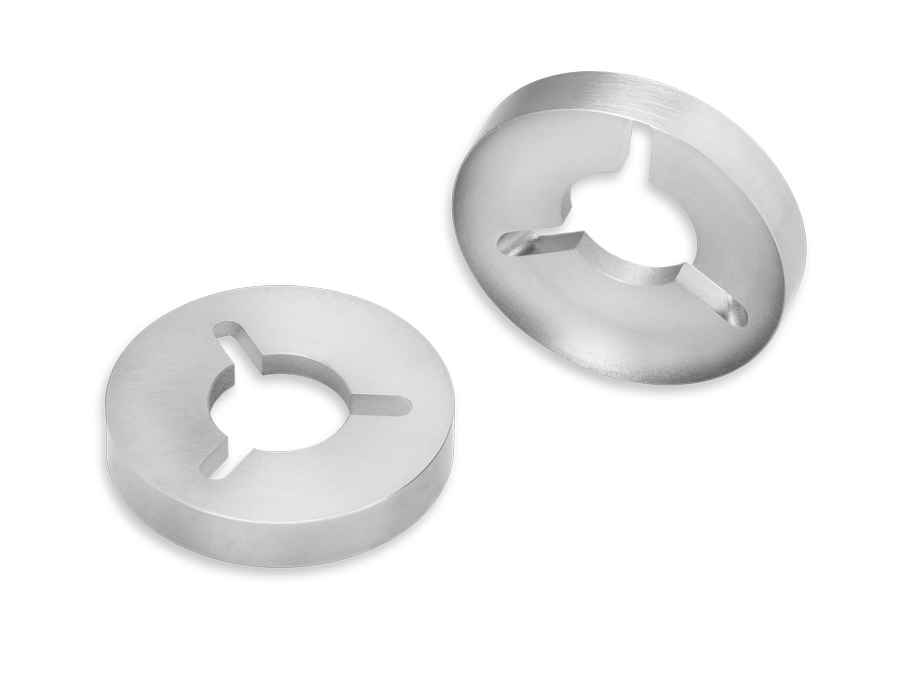

Machining tungsten - tungsten alloys

Tungsten is difficult to machine. It is highly resistant to any molding and machining operation (high tool wear). Machining tungsten and its alloys is simplified when the brittle-ductile transition temperature is observed. At room temperature, ductility (propensity to deform) is very low. Even small alloying additions shift the brittle-ductile transition temperature to lower temperatures. All tungsten alloys are therefore much more readily machinable than pure tungsten.

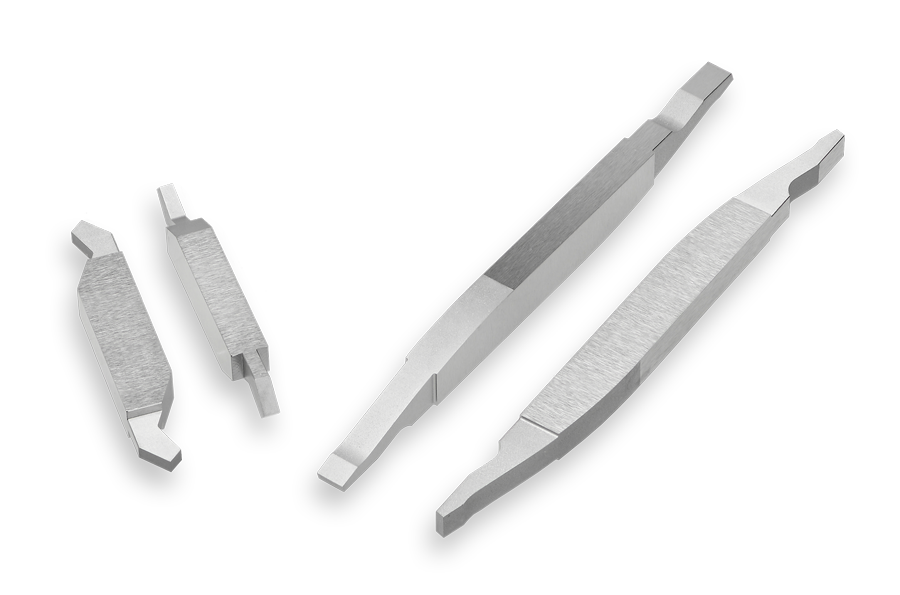

The more advantageous machining temperatures are significantly above the brittle-ductile transition temperature, which is, for example, approx. 200°C for a sheet thickness of 1 mm and approx. 380°C for a sheet thickness of 7 mm. Turning, milling with carbide, drilling with HSS and grinding with silicon carbide are possible. When punching, cutting and bending, the sheet thickness and the corresponding processing temperature must be taken into account. If possible, bending should be performed transverse to the rolling direction (microstructure in longitudinal direction). If this is not structurally possible, the processing temperature must be increased significantly. The bending radius must not be less than the plate thickness.

Riveting, bolting, soldering and welding are also possible, provided certain rules are observed. Riveting and bolting are to be preferred to soldering and especially to welding in order to avoid unnecessary stresses. The recrystallization temperature has a significant influence on the mechanical properties of all refractory metals and metal alloys in the high temperature range. Above the recrystallization temperature, a microstructural transformation occurs which results in a decrease in essential strength values and an increased tendency to fracture. For this reason, the aim is to achieve the highest possible recrystallization temperature. A high degree of deformation as well as the targeted alloying and introduction of additives significantly increases the recrystallization temperature. At the same time, the mechanical properties are optimized in relation to the area of application. The machinability is significantly improved.

Applications:

Boats for vapor deposition, round blanks for semiconductor manufacturing, power supply lines and anodes/cathodes for electron tubes, welding electrodes

Available formats:

Customer-specific solutions to drawing, electrodes and round rods in commercially available dimensions from stock, rods, pins, plates, wires

Bending temperature reference values

- at 1 mm thickness 300 – 400 °C

- at 4 mm thickness 600 – 700 °C

- at 7 mm thickness 650 – 800 °C

Punching and shearing temperature reference values

- at 1 mm thickness 400 – 500 °C

- at 4 mm thickness 850 – 950 °C

- at 7 mm thickness 950 – 1000 °C

Contact

Do you have a question or a suggestion? Do not hesitate to contact us. You can find the right contact person for your topic here.

Phone: +49 (0) 711 97948 – 0

Materials

Tungsten, tungsten-copper, tungsten heavy alloys, molybdenum, TZM or hard metal: our high-performance materials for your individual requirements.

Blanks from stock – fast shipping

We deliver over 20,000 parts in over 200 different profile dimensions directly from stock.

You order and we will ship on the day of the order!