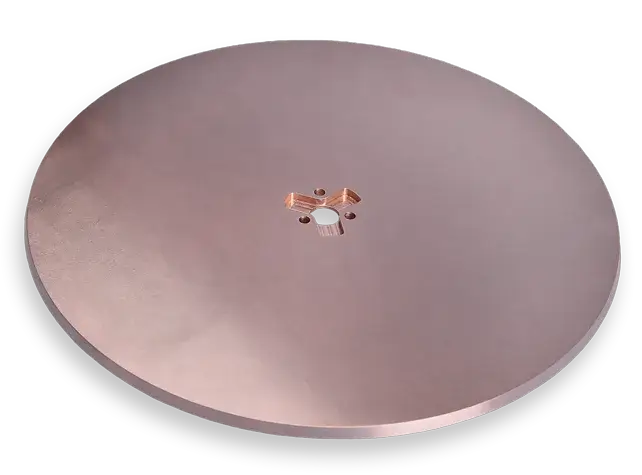

Tungsten-Copper

Has lots to offer, and even more depending on copper content. NHT’s brand name for sintered tungsten-copper is EROMET. It is predominantly manufactured with a tungsten:copper ratio of 80:20, 75:25 and 90:10.

EROMET is characterized by good machinability, high burn-off resistance, and by its outstanding electrical and thermal conductivity.

Applications for EROMET include sinking electrodes for spark erosion (EDM) and high-voltage and low-voltage switching contacts in electrical switchgear applications. Its principal properties include high temperature resistance, caused by the tungsten matrix, and the electrical and thermal conductivity, caused by the infiltrated copper content.

Properties

- High burn-off resistance

- Good electrical conductivity

- High thermal conductivity

- Low alloying propensity

- Good machinability

Applications

- Electrodes for sink eroding

- Electrodes for electro-chemical material removal

- Electrodes for resistance welding

- Contacts for electrical switchgear

- Thermodes

Available formats

- Formed parts to drawing

- Rods

- Plates

- Blocks

- Tubes

Physical features

Note: subject to technical changes. Minor deviations are production related.

Explanations: *sm=slight ferromagnetic; *pm=paramagnet

Contact

Do you have a question or a suggestion? Do not hesitate to contact us. You can find the right contact person for your topic here.

Phone: +49 (0) 711 97948 – 0

Materials

Tungsten, tungsten-copper, tungsten heavy alloys, molybdenum, TZM or hard metal: our high-performance materials for your individual requirements.

Blanks from stock – fast shipping

We deliver over 20,000 parts in over 200 different profile dimensions directly from stock.

You order and we will ship on the day of the order!