Wolfram-Schwermetall (WSM)

Der Alleskönner unter den Wolframlegierungen. Durch eine hohe variable Dichte lassen sich je nach Zuschlag von Eisen oder Kupfer ganz unterschiedliche Eigenschaften erzielen.

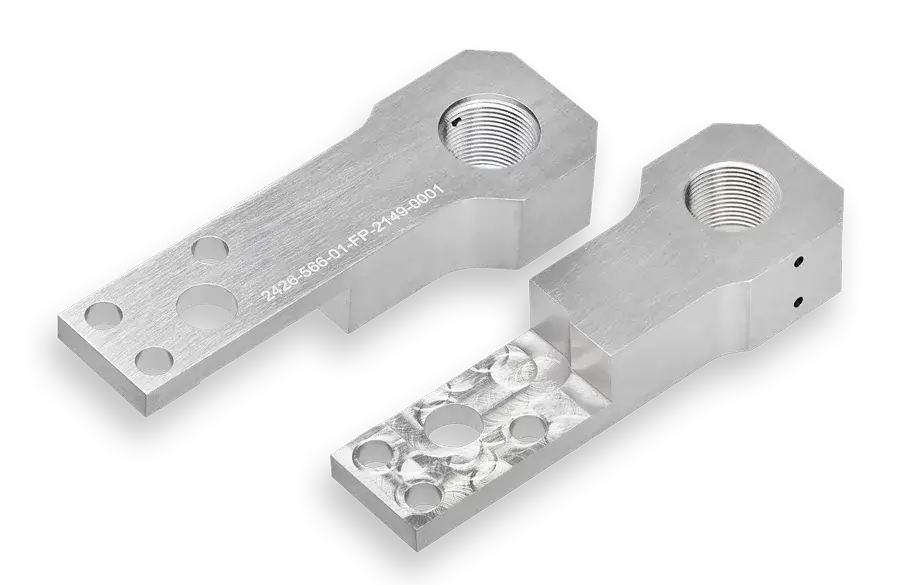

Wolfram-Schwermetall besitzt einen Wolframgehalt zwischen 85 und 98,5 Gew.-%. Der Rest besteht entweder aus leichtmagnetischem Nickel/Eisen oder nichtmagnetischem (paramagnetischem) Nickel/Kupfer. Hohe Dichten von 17 bis 18,5 g/cm³ sowie hohe Festigkeit und Duktilität zeichnen die Wolfram-Schwertmetalle aus. Die Bearbeitbarkeit von WSM ist im Vergleich zu chemisch reinem Wolfram deutlich leichter. Drehen, Fräsen und Bohren erfolgen mit Hartmetallwerkzeugen – auch Gewindebohren ist möglich. So können auch komplexe Bauteile nach Kundenzeichnung gefertigt werden.

Eigenschaften

- hohes Absorptionsvermögen

- hohe variable Dichte

- hoher Elastizitätsmodul

- gute Bearbeitbarkeit

Einsatzgebiete

- Bohrstangen, Drehmeißelhalter, Schleifscheibenschäfte

- Abschirmelemente, Kollimatoren für Strahlenschutz

- Ausgleichsgewichte für Kurbelwellen

- Wuchtgewichte für Generatoren und Turbinen

- Ambosse und Elektroden zum Warmstauchen

- Vibrationshämmer

- Uhrenindustrie

- Golfschläger (Putter), Dartpfeile

Lieferformen

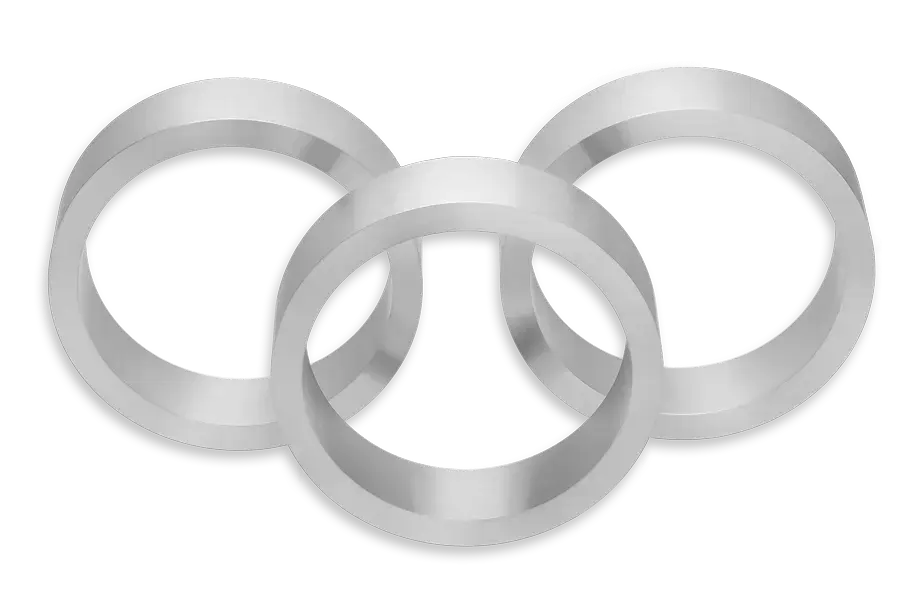

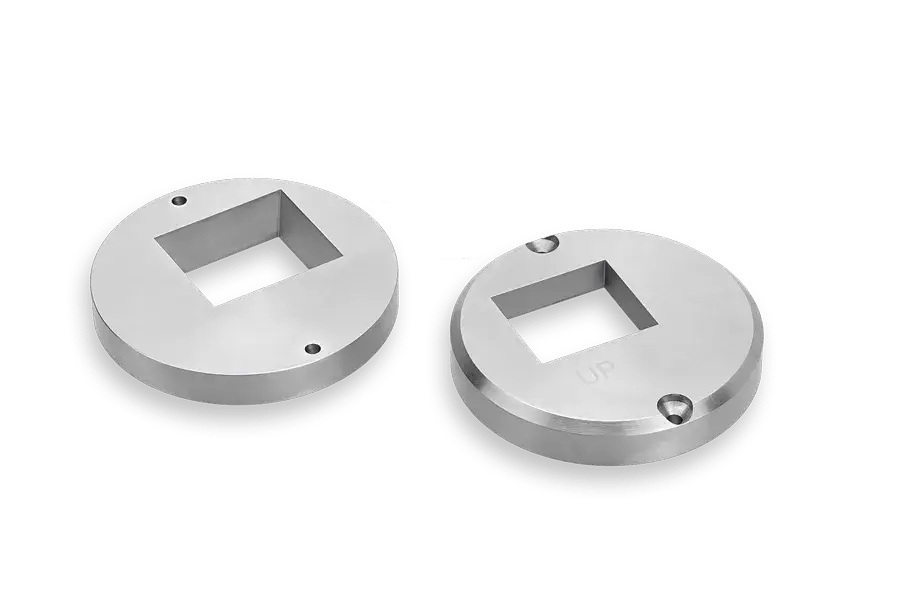

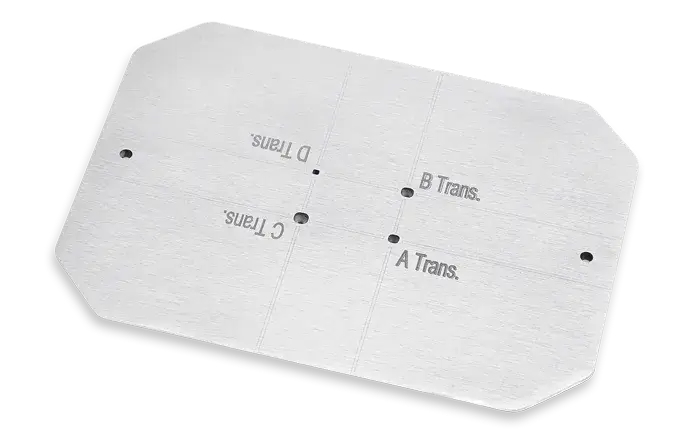

- Formteile nach Zeichnung

- Stäbe

- Platten

- Blöcke

- Bleche

Physikalische Eigenschaften

Anmerkung: technische Änderungen vorbehalten. Geringfügige Wertabweichungen sind produktionsbedingt.

Erläuterungen: *sm=slight ferromagnetic; *pm=paramagnetic

Kontakt

Haben Sie eine Frage oder eine Anregung? Zögern Sie nicht uns anzusprechen. Hier finden Sie direkt den richtigen Ansprechpartner für Ihr Thema.

Telefon: +49 (0)711 97948 – 0

Werkstoffe

Wolfram, Wolfram-Kupfer, Wolfram-Schwermetall, Molybdän, TZM oder Hartmetall: Unsere Hochleistungswerkstoffe für Ihre individuellen Anforderungen.

Rohlinge ab Lager – schneller Versand

Wir liefern Ihnen über 20.000 Teile in über 200 verschiedenen Profilabmessungen direkt ab Lager.

Sie bestellen und wir versenden noch am Bestelltag!